Our Process

Concept development & design

We work one-on-one with our clients to create upscale and unique pieces to suit your requests. Whether you already know what you’re looking for, or are just beginning to create your concept, we work with you to design for your needs and ultimate program goals.

manufacturing & creation

At Kennedy Incorporated, we control every detail of the manufacturing process at our state-of-the-art facility to ensure the highest level of quality. With the newest in automated robotic technology, we create specialized products without sacrificing efficiency.

Our Core Capabilities

Kennedy Incorporated possesses a number of unique competencies that set it apart from other precious and non-precious metal manufacturers. These include:

Manufacturing in a lean and green manufacturing facility including non-precious as well as precious metals

Specializing in die struck custom metal work, coining, precision machined parts, and all aspects of metal machining and forming.

Blanking and stamping including all secondary operations such as piercing and trimming. Other associated capabilities include progressive stamping and reel-to-reel stamping. The company also has an aluminum stamping capability that has allowed it to produce a high-volume product in a cost-efficient manner.

3D modeling and digital tooling capabilities for in house and customized projects

Clear coating (UV stable) process that provides excellent resistance to salt corrosion and handling damage without discoloration, peeling, or fracturing as well as excellent resistance to ultraviolet breakdown (especially over gold)

Polishing and finishing operations include deburring, sandblasting, hand polishing,and automated polishing operations for high volume projects.

Electroplating including copper, nickel, gold, and heavy silver electroplated finishes. MIL SPEC finishes are our specialty for military uses such as silver oxe, heavy gold, and bright nickel decorative finishes.

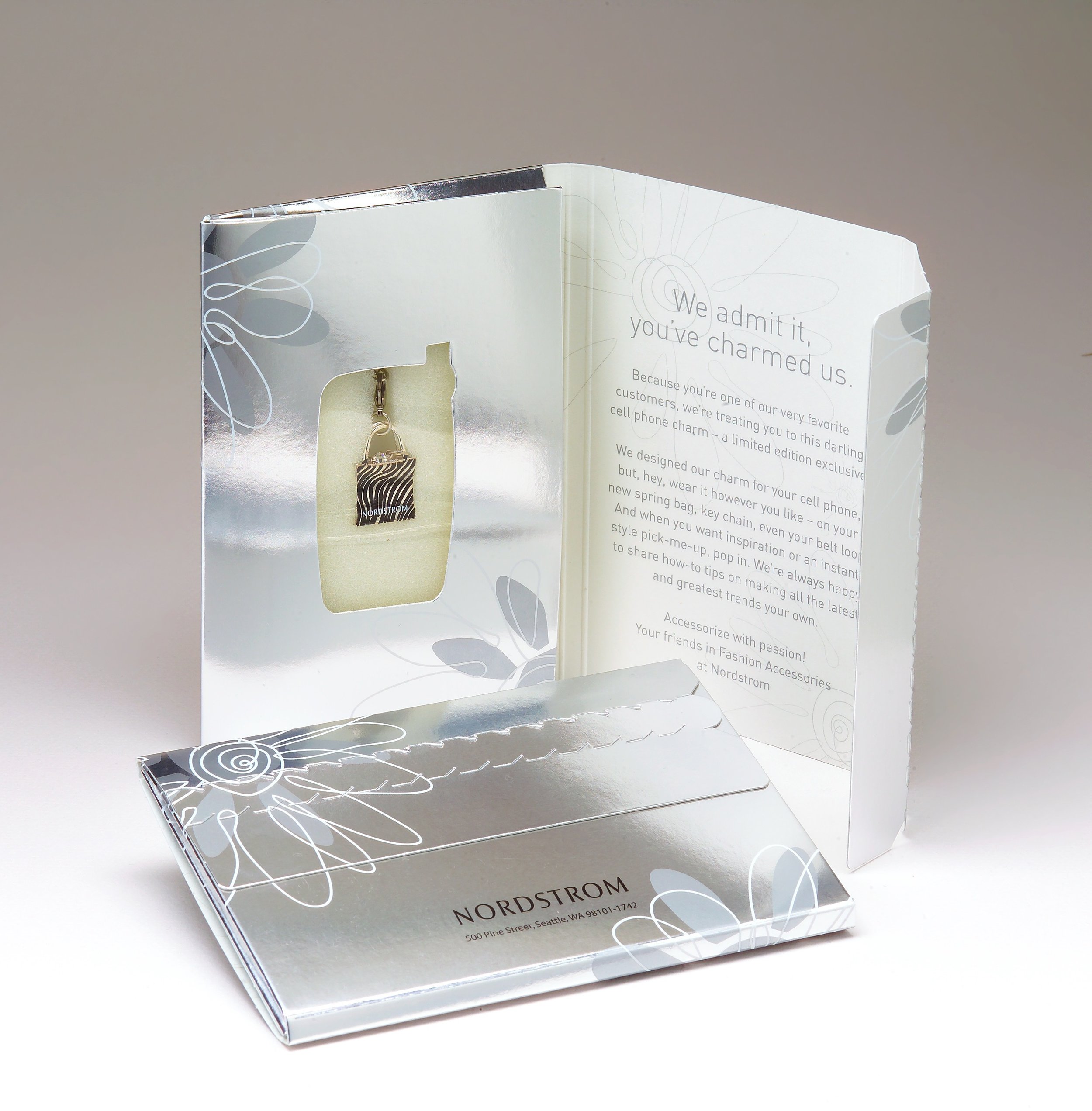

Custom packaging for turn key projects is a long time specialty for us. High volume production and packaging is our specialty.

The application of lean manufacturing principles and ongoing investment in automation to ensure the manufacture of the high volume products, in the shortest amount of time possible, with the least amount of overhead.

A plating operation that recycles all rinses and metals – generating tens of thousands of dollars in cost savings that get passed onto our clients each and every year.

Our Work

Kennedy Incorporated develops the most unique products available. See some of our custom work here.